Unlocking the Secrets of Vacuum Interrupter Testing

- KPM Tech Team

- Nov 23, 2025

- 3 min read

A vacuum interrupter is a core component used primarily in medium-voltage and high-voltage electrical circuit breakers. It’s a switch which uses a vacuum to extinguish the arc when the circuit breaker interrupts a current. Vacuum interrupter technology is used for repetitive switching, motor inrush current interruption, fault protection, overcurrent, and short-circuit protection.

Vacuum Interrupter Testing

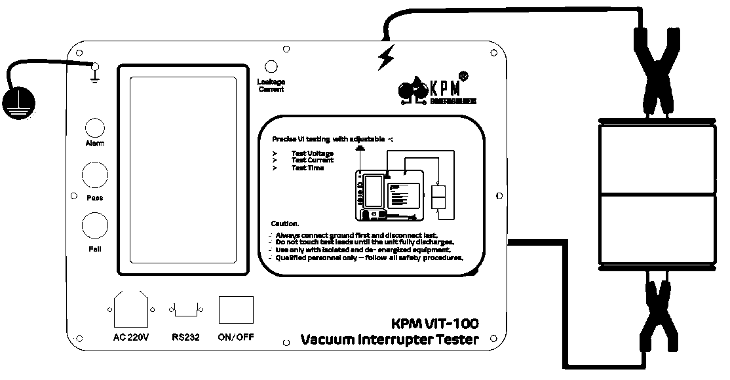

A vacuum interrupter tester works by applying a high DC voltage across the interrupter's open contacts to check for a loss of vacuum or other defects. A good vacuum interrupter will have high dielectric strength, preventing a flashover or excessive leakage current, indicated by a green light. If the interrupter is defective and the vacuum is poor, the tester will detect a flashover or high leakage current and indicate a failure . Vacuum Interrupter testing is mainly of 2 types -:

1) High voltage testing:

The tester applies a high-voltage DC pulse to the interrupter, which is usually open during the test.

2) Vacuum Testing ( Using Penning Discharge Principle ) :

The high vacuum inside a good interrupter prevents current from flowing across the open contacts. The VI test result is decided on basis of below-:

Pass: If the vacuum is intact, the interrupter resists the voltage, and the tester shows a "pass" indication, typically a green light.

Fail: If the vacuum is compromised, the interrupter can't withstand the voltage. This leads to a flashover or a high leakage current, which the tester detects and signals as a "fail" (e.g., a red light and/or a buzzer).

Why Vacuum Interrupter testing is done?

Over time, a vacuum interrupter can lose vacuum due to seal deterioration, contamination, mechanical wear, or simply aging. If the vacuum level drops too low, the interrupter may not withstand switching duties and could fail during operation. Testing helps identify these issues early, preventing faults, arc-flash incidents, and unplanned outages.

Reasons behind False or Misleading Test Results in Vacuum Interrupter testing.

Even a good vacuum interrupter can sometimes appear to “fail,” and a defective interrupter may occasionally seem to “pass” if conditions are not ideal. Common causes include:

Surface contamination on the interrupter terminals (dust, moisture, grease).

Humidity or condensation affecting the external creepage path.

Poor contact between test leads and terminals, creating unstable readings.

Inadequate grounding, leading to leakage paths or floating potentials.

Damaged or low-quality test leads that introduce noise or leakage currents.

Incorrect test voltage or test time settings that do not reflect actual conditions.

External electrical noise or switching activity nearby.

Interrupter not fully open or mechanical mechanism not latched properly.

Because of these factors, if a result appears abnormal, retesting after correcting the environment or connections is often necessary.

Importance of the Vacuum Interrupter Test.

Vacuum interrupters are central to the safe operation of medium- and high-voltage switchgear. Their failure can lead to severe equipment damage and safety hazards. Regular testing supports predictive maintenance, helps avoid costly downtime, and ensures that switching devices operate as intended under load.

Precautions to Follow during Vacuum Interrupter Testing.

High voltage is present during testing—maintain a safe distance from all terminals.

Always connect the earth/ground first and disconnect it last.

Allow the tester to fully discharge before touching or moving any leads.

Do not exceed the interrupter’s rated test voltage.

Check all leads, clips, and connectors for damage before starting.

Perform tests only in dry, clean conditions to avoid false leakage paths.

Wear appropriate PPE and follow standard high-voltage safety practices.

Ensure only trained personnel handle vacuum interrupter testing.

Comments